EffiBOT-P operates autonomously, navigating between docks, wrapping stations, and storage areas. It connects seamlessly with conveyors and your site’s physical and digital infrastructure, such as automatic doors, machinery, ERP, WMS, and more.

Equipped with multiple sensors, it moves safely in mixed environments alongside operators and other machines.

Its navigation system ensures:

Obstacle avoidance

Emergency stops

Priority management

Compliance with warehouse traffic and safety rules

EffiBOT-P can perform precision tasks, like counting and picking the exact number of pallets required by a mission.

Autonomous operation requires mapping via MapEditor and mission setup in our fleet management system, EffiFCS

EffiBOT-P connects to WMS, MES, and ERP systems to automatically generate tasks and ensure full traceability of transported goods. Equipped with a Smart Code Scanner, it can read both barcodes and QR codes, enhancing reliability and tracking throughout your operations.

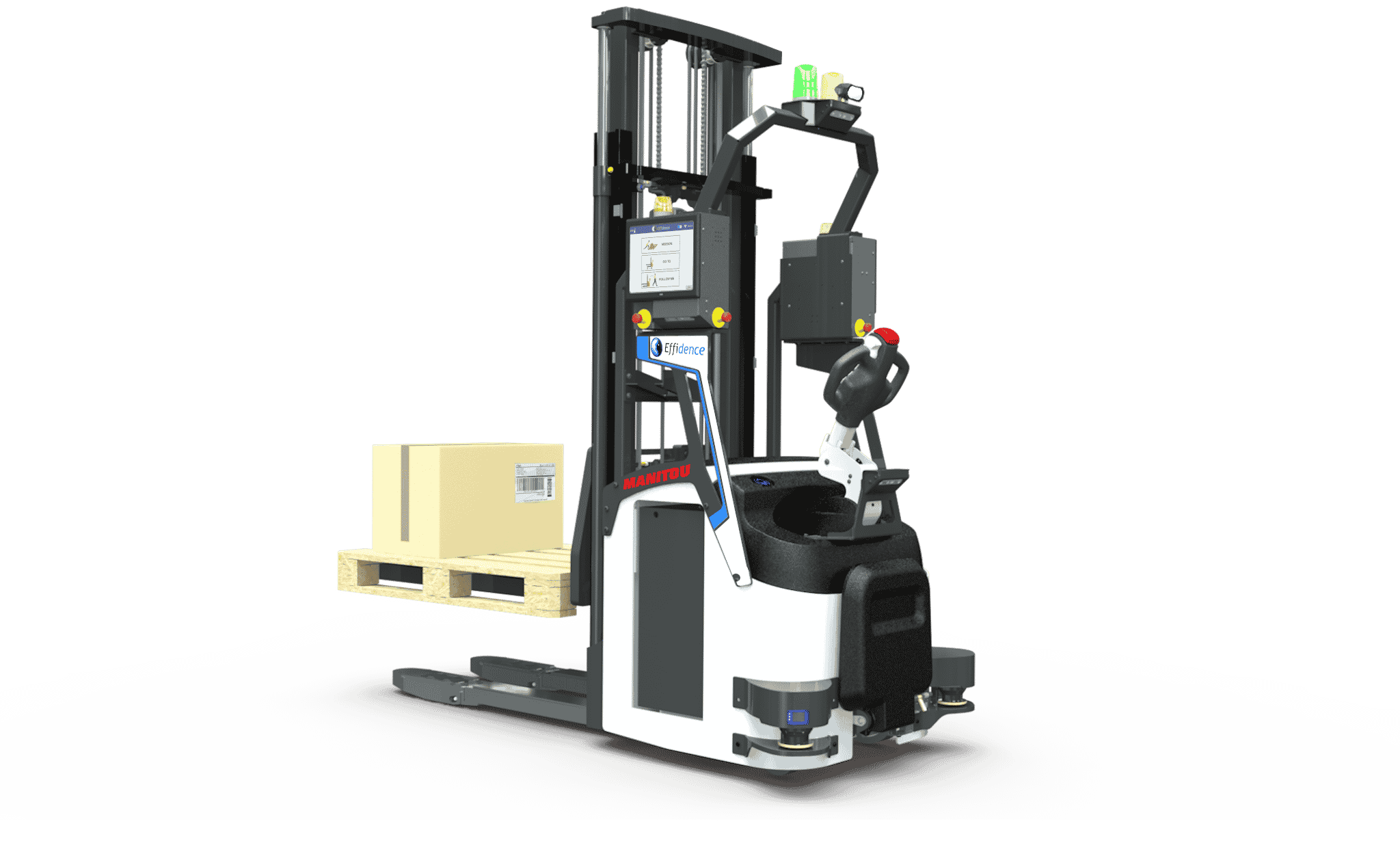

Our stackers are equipped with:

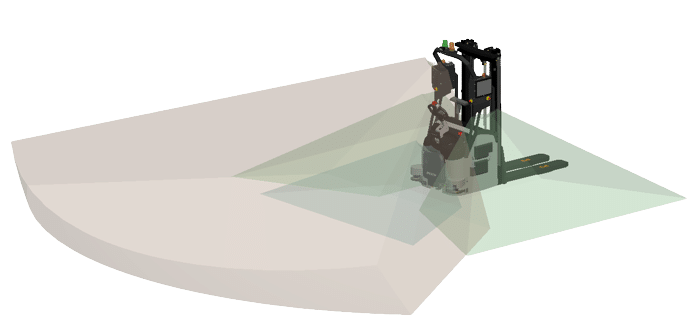

2 LIDAR sensors with 270° detection for navigation and obstacle avoidance

3D cameras to detect high or low obstacles, such as forklift forks

Telemeters for lateral safety up to the tip of the forks

Front sensor for accurate pallet handling

1 3D LIDAR for enhanced perception

We also offer the EffiBOT-P80, a narrower model, and the EffiBOT-PF, a counterbalanced version designed for transporting closed pallets.

Load and lifting capacity: 1.6 T.

Length: 2240 mm.

Width: 985 mm.

Height: 2125 mm.

Load and lifting capacity: 1.6 T.

Length: 2277 mm.

Width: 800 mm.

Height: 2125 mm.

Load and lifting capacity: 1.6 T.

Length: 2601 mm.

Width: 1076 mm.

Height: 2133 mm.

A set of sensors analyzes the environment with a 270° field of view

Localization is primarily based on natural landmarks and can be enhanced with artificial markers in open areas

The navigation system supports speeds of up to 6 km/h (1.7 m/s)

We will be happy to answer all your questions and help you find a suitable solution.