If you’re looking for professional services using modern laser cutting technology, you’ve come to the right place. Thanks to our laser, we can cut a wide variety of materials with high precision according to your specifications. The result is precise sheet metal cuts that meet even the highest standards. Join our satisfied customers and send us an inquiry.

We have joined forces with the world leader in high-performance laser cutting machines. Our innovative solutions deliver unmatched precision and efficiency for processing a wide range of materials. With our wide range of 2D and 3D laser cutting machines as well as tube laser cutting equipment, we are ready to meet all your laser cutting needs. Join thousands of satisfied customers worldwide. Our supplier is one of the leading export brands from China. This is thanks to the largest range of beveling machine installations in the world and leads in installations of 2D laser cutting machines over 20KW. Therefore, we can say with a clear overview that PENTA LASER machines enable precise and fast cutting of metals and non-metals. Choose PENTA LASER for efficient and reliable material cutting.

Laser cutting is a non-contact method of material separation that allows precise cutting of both metallic and non-metallic materials with varying thicknesses. The process uses a focused laser beam that is accurately directed and concentrated into a very small point—usually less than half a millimeter in diameter. When the beam hits the surface of the material, it heats it to the point of melting or evaporation. If more heat accumulates at the point than can be dissipated, the beam penetrates fully through the material—this marks the start of the cutting process. Unlike conventional methods that apply significant mechanical force, the laser operates without touching the material, eliminating tool wear and preventing deformation or damage to the workpiece.

Laser cutting enables precise and reliable processing of a wide range of industrial materials — from steel, aluminum, and stainless steel to plastics, glass, wood, and ceramics. With the ability to cut sheet thicknesses from 0.5 mm to 30 mm, laser cutting is a top choice for diverse applications in metalworking and non-metal material processing.

The focused laser beam heats only a localized area of the material, leaving the rest of the workpiece thermally unaffected. This results in minimal kerf width and allows even the most complex and delicate contours to be cut cleanly and burr-free. In most cases, no post-processing is required. This makes laser cutting ideal for prototypes, small production runs, and products with high variability.

Ultrashort-pulse lasers vaporize nearly any material so quickly that there is no significant thermal effect. This produces smooth, high-quality edges without molten residue. These lasers are perfect for creating fine metal components, such as stents in medical technology, and are also used in the display industry for cutting chemically hardened glass.

Efficient and accurate CNC laser programming is essential to maximizing the performance of any laser cutting system. At Pro Tool Solutions, our skilled programmers use advanced software and techniques to translate your design files into precise machine instructions, ensuring flawless execution and consistent results across every project.

Whether you need a single prototype or full-scale production, our team creates custom cutting paths that are optimized for speed, material efficiency, and laser accuracy. This careful programming reduces cycle times, minimizes waste, and improves the overall cost-effectiveness of your production process.

We work with a variety of file formats including PDF, DXF, JPG, DWG, and CDR, and adapt each design to the specific requirements of your chosen material and final product. By optimizing the laser’s movement and power settings, we ensure a clean, high-quality finish every time.

Explore how our CNC laser programming can streamline your workflow and improve productivity—reach out to us or consult our laser service pricing guide for more details.

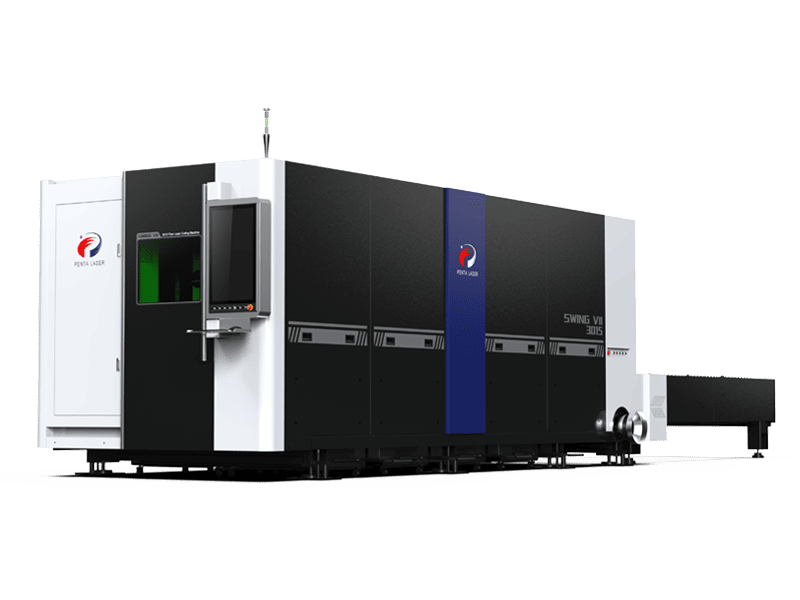

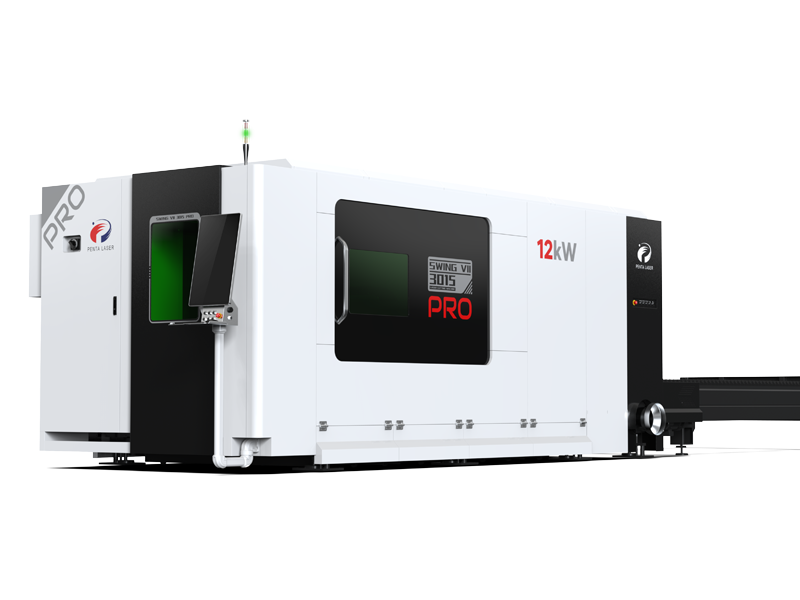

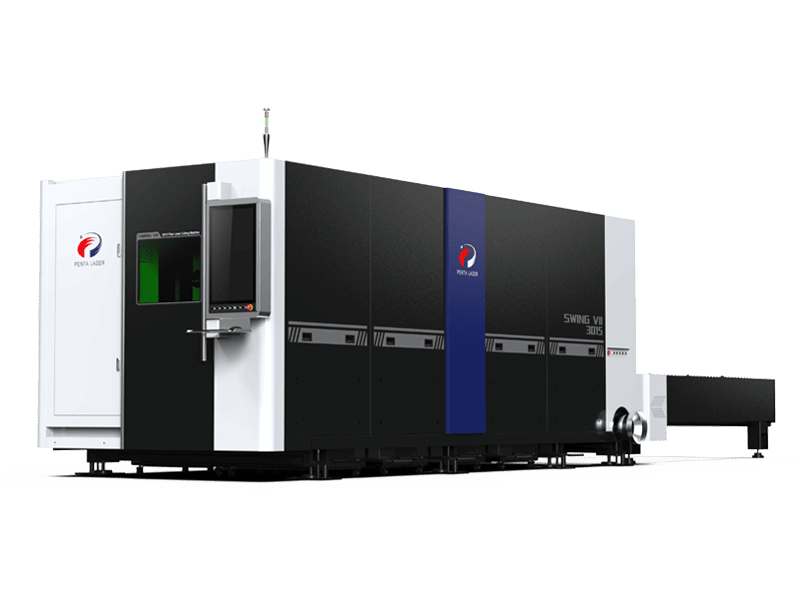

High-Precision Laser Cutting with the SWING VII 3015

At Pro Tool Solutions, we utilize the SWING VII 3015, a powerful and reliable fiber laser cutting system tailored for industrial and mechanical manufacturing. This machine stands out for its consistent performance, precision engineering, and operational efficiency—making it an excellent fit for both custom fabrication and large-scale production.

Main Technical Capabilities:

This advanced laser system ensures optimal results on a wide variety of materials, thanks to its high-speed motion control and exceptional stability. The SWING VII 3015 helps us maintain tight tolerances and clean cuts—boosting productivity without compromising quality.

In the field of industrial metal fabrication, maintaining high-quality standards is crucial. At Pro Tool Solutions, we conduct rigorous laser cutting quality control using advanced optical measurement tools. This ensures each part is produced with exacting accuracy and allows us to confidently fulfill complex and highly specific customer requirements.

Our laser cutting rates are calculated based on several key factors, including:Material type and thicknessGeometric complexity of the cutting pathTotal number of cuts requiredThanks to the speed and efficiency of our CNC laser systems, this method is highly cost-effective for both small-scale and high-volume orders. If you’d like a customized quote, don’t hesitate to get in touch with our team for more details.

We will be happy to answer all your questions and help you find a suitable solution.