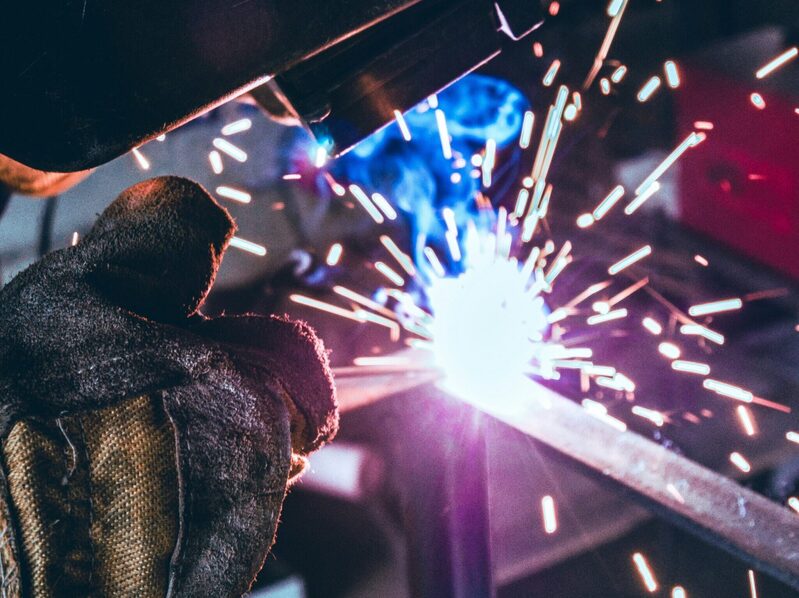

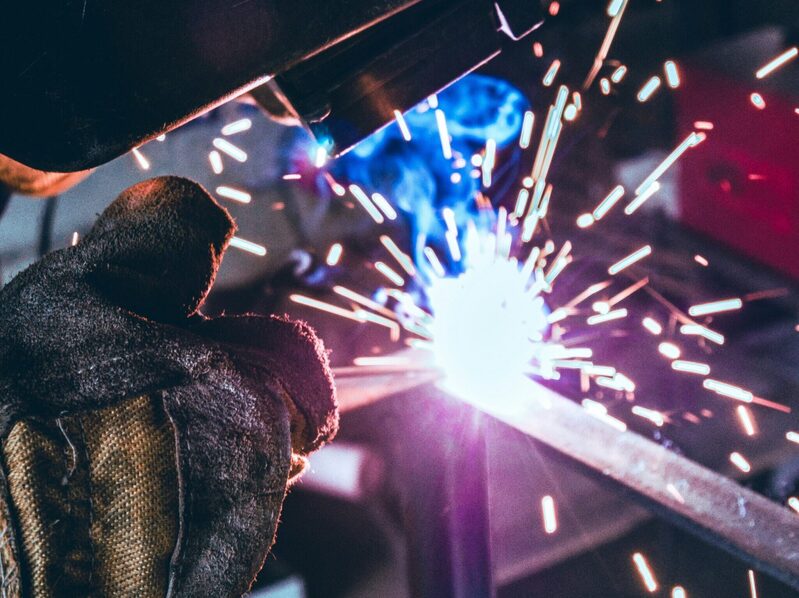

Thanks to our extensive technological background and wide range of welding processes (MIG, MAG, TIG), we are experts in the manufacture and processing of welded structures made from a variety of materials. Whether small or large, light or heavy, we are here for you! Custom-made products based on your specifications or our designs are our specialty. Your vision, our solution!

Do you need to manufacture metal mesh, fences, stairs, or other welded joints for industrial production? Benefit from our extensive technological expertise and a wide range of welding methods, including MIG, MAG, and TIG welding.

We manufacture and process weldments from a variety of materials, in small and large sizes (max. approximately 1 ton), for a wide variety of applications. Weldments are manufactured to order, both individually and in series, according to the documentation provided.

Welding involves joining two or more materials, usually metal, to form a strong and indestructible joint – a weld. This joint is created by the action of heat, pressure, or a combination of both, which changes the structure of the material around the joint.

The goal of welding is to create a strong, permanent joint that can withstand mechanical and thermal stress. To achieve this, suitable conditions must be ensured for interatomic bonds to form. The resulting product is called a weldment and can have various shapes and sizes – from small components to large structures.

Not only metals can be welded, but also other materials. For successful welding, it is important that the materials have suitable weldability – for steel, for example, the carbon content (ideally up to 0.22%) is a crucial factor. Depending on the type of material and the desired properties of the joint, different welding processes are used, whether manual, semi-automatic, or fully automatic.

Welding offers several advantages, including high strength, durability, and weld integrity. This process enables efficient joining of materials, resulting in shorter production times and increased productivity. Compared to cast structures, welding can save up to 50% of material, reducing production costs and the weight of the final product.

Another advantage is the ability to replace worn or damaged parts, making welding a key process in the repair industry. Thanks to its flexibility, even complex structural designs can be implemented quickly, which is particularly advantageous for one-off and small-batch production.

We specialize in manufacturing a wide range of welded structures and products used in industry, construction, and design. Our most commonly produced welded structures include:

Welding is a key technology in many industries. The main application areas include:

Design and Technical Preparation

Before the actual welding, it is important to carefully review the structural design and technical documentation of the welded element. It is important to:

Evaluate the weldability of the base material

Select the optimal welding technique

Select a suitable filler material

Consider the possibilities for series production and the overall economic perspective

To achieve a high-quality weld, thorough removal of impurities is essential. This means eliminating coatings, oxides, and rust from the welding surfaces. This is achieved through mechanical processing, such as milling.

A careful material preparation and the correct technological procedures ensure that the weld achieves the best possible mechanical properties. The most common methods include:

Normalizing Annealing

It ensures a uniform distribution of mechanical properties and is mainly used for non-alloyed steels and thicker weld seams.

Refinement

It improves the ductility and toughness of the weld, thereby increasing the tensile strength of the welded joint and providing the necessary plastic properties.

Soft Annealing

It softens the structure and helps achieve the lowest possible hardness and good weldability in alloyed structural steels.

Preheating

The material is heated to 100–400°C (in exceptional cases up to 700°C), minimizing the temperature drop during welding and reducing the risk of cracks in the weld.

Arc welding is a process in which two workpieces are fused at the joint using an arc and filler metals (or without them in some processes). There are various welding methods; the choice of the most suitable method depends on the properties of the base material, the type of joint, the welding position, the required weld quality, and production efficiency. Below we list the welding methods we implement in Pro Tool Solution. Laser welding can be found here.

It is the oldest but still widely used method of arc welding. It is valued for its versatility, use in all welding positions, and the easy availability of welding sources and filler materials. Compared to semi-automatic and automatic processes, it has a lower melting efficiency but delivers high weld quality and good mechanical properties.

In covered electrode arc welding, the base material (weld pool) melts together with the flux-coated metal electrode. The flux performs a metallurgical, gas-forming, and ionizing function. During arc welding, the electrode melts, and the metal is incorporated into the weld pool, creating a solid weld.

This type of welding includes several processes based on the same principle but differing in the use of various welding wires and shielding gases:

MIG/MAG arc welding is one of the most commonly used welding processes. Thanks to its automation and robotization capabilities, it is ideal for mass production. This welding method can be performed in all positions, offers high deposition rates, and allows for a wide selection of shielding gases and filler materials.

During MIG and MAG welding, an arc forms between the melting electrode and the base material (weld pool). Welding wires can be either solid or tubular (filled with flux or metal powder). The shielding gas, whether inert or active, protects the weld pool and the wire throughout the welding process.

This welding process requires a high level of skill and experience from the welder. If the entire technological process is correctly followed, very high-quality welds can be achieved. TIG welding is most commonly used for welding materials such as aluminum, magnesium, stainless steel, and other metals with a high affinity for oxygen.

In TIG welding, an arc is formed between a non-consumable tungsten electrode and the base material (weld pool) in a shielding gas atmosphere. During this process, the weld edges of the base material and the filler metal fuse together, creating a strong, high-quality weld.

In general, welding can be performed in various positions, but some welding methods may offer limited positioning options. Selecting a suitable welding position is crucial, as it affects not only the quality of the weld but also labor productivity and, therefore, the cost of the welding process.

The direction and position of the weld are usually specified by the design drawing. Positioners are typically used to ensure the correct relative position of the welded parts. Horizontal from above – (electrode vertical) – PA symbol

After the welding process is completed, it is necessary to perform a dimensional and visual inspection of the welds, remove spatter, and conduct tests to verify the mechanical properties of the welds, metallographic tests, and defectoscopic or technological tests. Depending on the requirements, the welds can also be heat treated.

This process, carried out at a temperature of 820–950 °C, aims to remove coarse grain structure and refine the microstructure of the welded joint. This achieves good ductility and toughness, which improves the mechanical properties of the welded material.

This process is applied to unalloyed steels at temperatures of 500–650 °C. Its purpose is to minimize residual stresses in the material, thereby reducing the risk of dimensional changes during subsequent processing or when the welded structure is used under real-world conditions.

This process is performed on alloyed steels at a temperature of 650–750 °C and aims to eliminate internal stresses while simultaneously softening the weld and the heat-affected zone. The result is improved plastic and mechanical properties of the weld.

After welding is completed, further machining of the welds may be required, usually using CNC machines. This step can include grinding, milling, turning, or drilling, depending on the product requirements.

To minimize post-processing, it is very important to carefully check the accuracy and flatness of the welded parts during the welding process. By correctly adjusting the welding parameters (temperature, speed, welding method, etc.), the required dimensions and properties of the weld can be achieved. This not only reduces the time and cost required for further processing but also improves the overall quality of the products.

Welding is a high-risk activity, so it’s important that occupational health and safety are always a top priority. Only qualified personnel with a valid welding license are allowed to work. All welding work at Pro Tool Solutions is carried out under professional workshop supervision. Adequate protective equipment such as sturdy footwear, protective clothing, leather gloves, an apron, and a welding helmet are essential.

Furthermore, we attach great importance to ensuring that the welding workplace complies not only with safety regulations but also with hygiene and other legal standards. We ensure appropriate climatic conditions and the extraction of fumes, including harmful gases, vapors, smoke, and dust. We also perform regular welding unit maintenance and nozzle cleaning to minimize welding complications and ensure a safe and efficient work environment.

The welding price depends on several factors, such as the size and complexity of the weld, the welding method used, and the type of material. We offer both one-off and series production, allowing us to respond flexibly to the needs of small and large companies. Before you could get in touch, the radio started playing.

We will be happy to answer all your questions and help you find a suitable solution.